News

[Sablux news July issue] I introduce a maker product according to our handling of the favorable reception to Sablux company product user!

2021-07-14

注目オススメ

Firstly it is ...

The Sablux news delivers it to user having you already use our handling product, the customer whom the product examines for the purpose of providing useful information and to be able to utilize.

The Sablux company product which is the handling product of our UNITEK JAPAN in the Sablux news

- UNICLEAN (screw, die washing blast device)

It is blast Cleaning machine specialized in the washing of a screw, the die. It is the device which I can wash without giving a screw, the base material of the die damage by using blast agent of the thermosetting resin.

- UNIFINISH (metal surface processing blast device)

It is the blast device which can plan die polishing, Bali collecting, surface minute mold release characteristics, fluid improvement.

I can make the metal surface minute as a blast processes the metal surface using alumina, two kinds of blast agent of glass beads.

Adjusting it from urtra-low air pressure (0.03MPa) is possible and can handle corner anyone, dimensions change regardless of the technology of the worker in spite of being a guard besides.

I will send the above, UNICLEAN, the use results of the UNIFINISH.

I introduce a maker product according to our handling of the favorable reception to Sablux company product user!

I do an introduction of the resin pressure sensors made in GEFRAN company this time.

In Gefran company, there is the history for 50 years in a company located in the northern part of Italy which did sensor production and sales if main.

I offered components to an automation system and the industrial process control plane to a base in knowledge, know-how accumulated in a history.

As of 2016, there are 100,000 Sale examples, agency 80 companies, 17 stores.

★With the resin pressure sensors,

It is to a sensor measuring pressure of the melted resin used for Forming machine such as the extrusion.

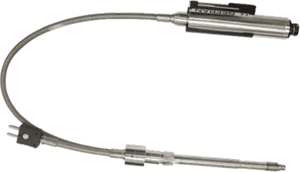

★Resin pressure sensors IMPACT type made in GEFRAN company

As for the IMPACT type, enclosure liquid becomes an unused model.

It is kind to environment and becomes at low risk of having been damaged.

In addition, for enclosure liquid mint condition, a diamond Fulham part of the tip is 15 times of conventional products,

I adopt GEFRAN company's original GTP+ coating in addition to that,

It becomes the resin pressure sensors of the unprecedented high life of the guarantee for two years.

Resin pressure sensors lineup

Rigid rod

Flexible rod plus thermocouple

Flexible sheath

Exposed tips

★Single floating specifications

As for the single floating, only the tip turns around; is typed. Therefore installation, disassembly are easy and are less likely to break down at time.

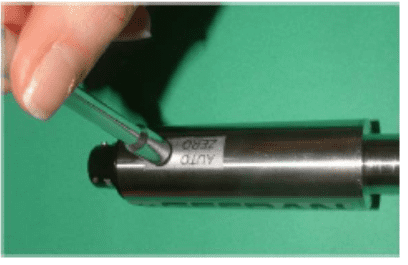

★Automatic zero setting with the touch pen

I can proofread zero easily just to push it with a touch pen like a photograph with pi.

The convenience becomes the good resin pressure sensors by high life, too.

I would appreciate your asking it to the following contact information if you have any questions.

[Osaka Head Office]

〒563-0025 2-7-6, Jonan, Ikeda-shi, Osaka Kanda second building

TEL: +81-727-54-5757 FAX: +81-727-54-5758

〒563-0025 2-7-6, Jonan, Ikeda-shi, Osaka Kanda second building

TEL: +81-727-54-5757 FAX: +81-727-54-5758

[Yokohama Office]

〒222-0033 2-12-12, Shinyokohama, Kouhoku-ku, Yokohama-shi, Kanagawa

TEL: +81-454-70-0177 FAX: +81-454-70-0178

〒222-0033 2-12-12, Shinyokohama, Kouhoku-ku, Yokohama-shi, Kanagawa

TEL: +81-454-70-0177 FAX: +81-454-70-0178

[YouTube] You can see ← washing, the surface treatment video in YouTube.

Official SNS of the UNITEK JAPAN