Sensoptic company sole agent

Sensoptic Company introduction

SENSOPTIC was founded in 1998 by Axel Bertholds and Andreas Braunschweiler as a spin-off company of GF Machining Solutions, Losone, following ten years of development and production of optical sensors for wire electro-discharge machines. The Company remained in the same facilities located in the italian speaking Canton of Ticino in Southern Switzerland, and is privately owned and managed by the founders.

Thanks to its extensive know-how in optical sensor technology and micro engineering, SENSOPTIC was originally established as a designer and manufacturer of innovative precision instruments for a wide variety of customized sensor applications. Some years later, recognizing a market demand of measuring systems for quality control of small defects on fine wires and filaments, SENSOPTIC focused its efforts in offering a unique and proprietary range of automatic measuring systems. Boosted up by an increasing demand of high quality wires and filaments from European companies and a deeper understanding of customers manufacturing processes, this activity grew steadily with time to become the core-business of SENSOPTIC.

Thanks to its extensive know-how in optical sensor technology and micro engineering, SENSOPTIC was originally established as a designer and manufacturer of innovative precision instruments for a wide variety of customized sensor applications. Some years later, recognizing a market demand of measuring systems for quality control of small defects on fine wires and filaments, SENSOPTIC focused its efforts in offering a unique and proprietary range of automatic measuring systems. Boosted up by an increasing demand of high quality wires and filaments from European companies and a deeper understanding of customers manufacturing processes, this activity grew steadily with time to become the core-business of SENSOPTIC.

the priciple of measurement with Sensoptic system

various sensors

You can see examples of installation of various sensors in the production line, system structure, product introduction.

introduction

Sensoptic provides noncontact surface roughness defect detection system (optical sensor head, data collector, software) of extremely small diameter products using optical sensors as core technology.

The recommended application

・Monofilaments for industrial and medical applications

・Bare and coated wires for the electronics industry

・Optical fibers for telecommunications

・Multifilaments for technical textiles

・Monofilaments for industrial and medical applications

・Bare and coated wires for the electronics industry

・Optical fibers for telecommunications

・Multifilaments for technical textiles

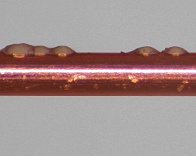

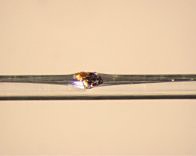

Product introduction (photograph)

FAULT DETECTION EQUIPMENT FOR WIRES AND FILAMENTS

Sensoptic supplies turnkey measuring systems controlled by personal computers which include proprietary PROFILE SENSORS, SENSYSTEM hardware for data acquisition and SENSOFT software for data management.

Features

・Can be fully integrated into any manufacturing process for continuous on-line quality control of multiple lines

・Portable configurations for off-line sample inspection in production or laboratory environments

・Runs on Windows based ordinary personal computers

・Multi-function, reliable and user-friendly SENSOFT software

・Up to 32 PROFILE SENSORS connected to one SENSYSTEM unit controlled by a single personal computer

・Configurations available for single-axis and dual-axis measurements, diameters from 0.01 mm to 4 mm and line speeds up to 2000 m/min

・Can be fully integrated into any manufacturing process for continuous on-line quality control of multiple lines

・Portable configurations for off-line sample inspection in production or laboratory environments

・Runs on Windows based ordinary personal computers

・Multi-function, reliable and user-friendly SENSOFT software

・Up to 32 PROFILE SENSORS connected to one SENSYSTEM unit controlled by a single personal computer

・Configurations available for single-axis and dual-axis measurements, diameters from 0.01 mm to 4 mm and line speeds up to 2000 m/min

PROFILE SENSORS

Sensoptic designs and manufactures precision optical sensors for non-contact detection of defects in fine wires and filaments. To satisfy today’s demanding quality control standards, our PROFILE SENSORS are as essential as laser micrometers for diameter measurements.

Features

・Non-contact measurement in one or two planes

・Diameters from 0.01 mm to 4 mm

・Line speeds up to 2000 m/min

・Detection of defects with micrometric resolution

・Compact design for narrow parallel lines

・Reliable operation even under rough conditions

・Insensitive to ambient stray and intense light

・No moving parts, low maintenance, long lifetime

・Non-contact measurement in one or two planes

・Diameters from 0.01 mm to 4 mm

・Line speeds up to 2000 m/min

・Detection of defects with micrometric resolution

・Compact design for narrow parallel lines

・Reliable operation even under rough conditions

・Insensitive to ambient stray and intense light

・No moving parts, low maintenance, long lifetime

As the type of the sensor has the following types, please refer.

Type of the sensor

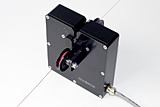

Data acquisition hardware "Sensystem"

The SENSYSTEM serve to run PROFILE SENSORS from a Windows based personal computer. They include all hardware for data acquisition, input connections for the sensors and an output USB connection to the computer.

The type depends on the number of the connected sensor heads.

The type depends on the number of the connected sensor heads.

Type of data acquisition hardware "Sensystem"

Data acquisition management software "Sensoft"

"Sensoft Standard"

Features

・Continuous monitoring of single or multiple lines with the same filament diameters and speeds

・Real-time visualization of statistics and quality parameters

・Intelligent detection of faults beyond specified threshold values

・Automatic data recording and data saving for post-processing

・Elaboration and printing of production quality reports

・Continuous monitoring of single or multiple lines with the same filament diameters and speeds

・Real-time visualization of statistics and quality parameters

・Intelligent detection of faults beyond specified threshold values

・Automatic data recording and data saving for post-processing

・Elaboration and printing of production quality reports

"Sensoft SPECTRO"

"Sensoft ML"

Features

・Continuous monitoring multiple lines with different diameters and speeds

・Real-time visualization of statistics and quality parameters

・Operation can be fully automated through database reading of diameter, line speed and spool changes parameters

・Automatic data recording and data saving for post-processing

・Elaboration and printing of production quality reports

・Continuous monitoring multiple lines with different diameters and speeds

・Real-time visualization of statistics and quality parameters

・Operation can be fully automated through database reading of diameter, line speed and spool changes parameters

・Automatic data recording and data saving for post-processing

・Elaboration and printing of production quality reports